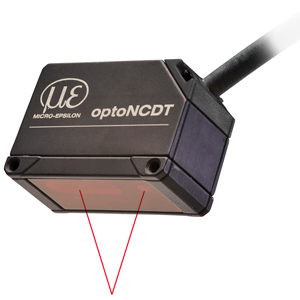

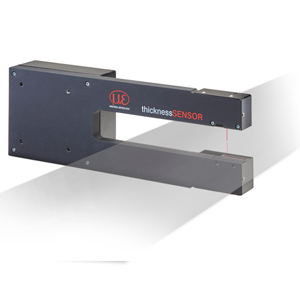

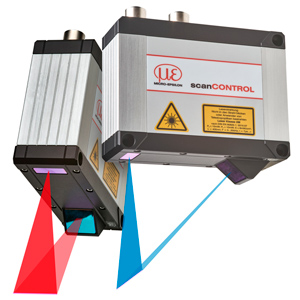

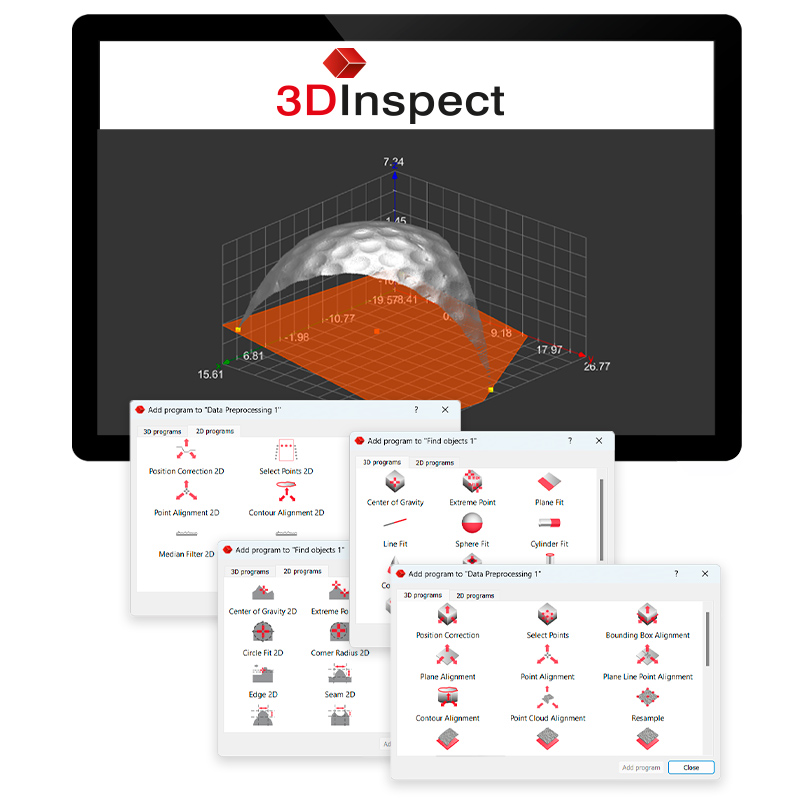

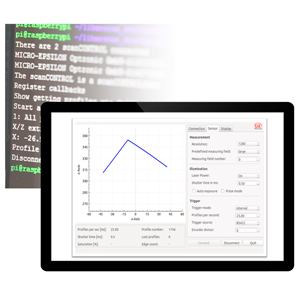

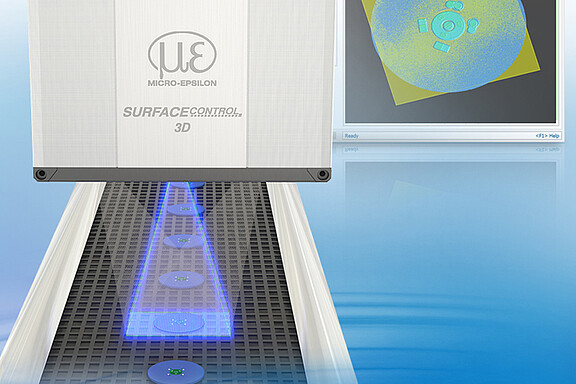

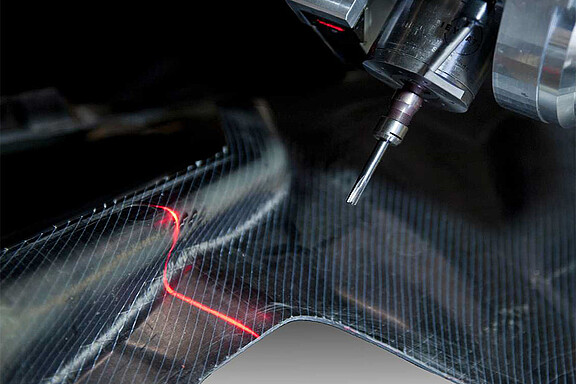

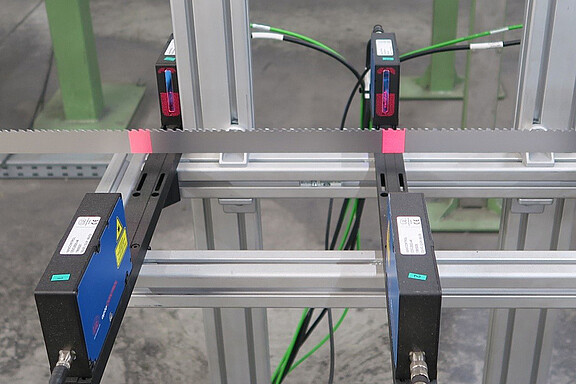

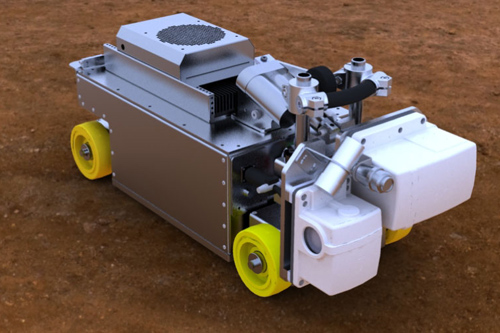

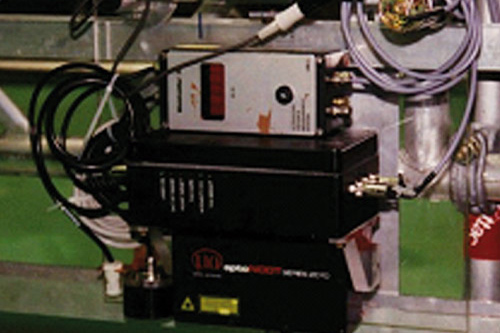

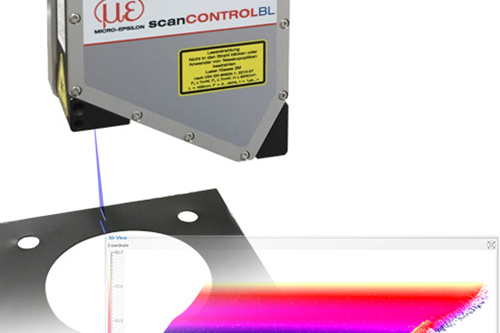

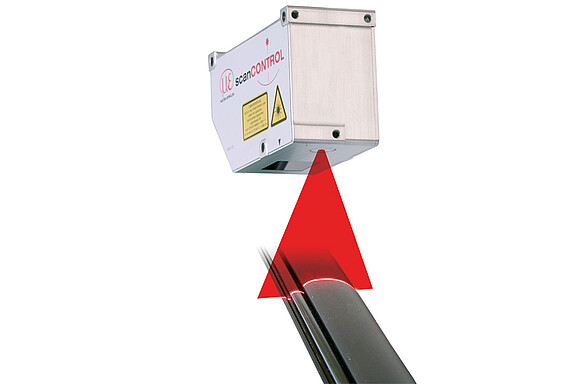

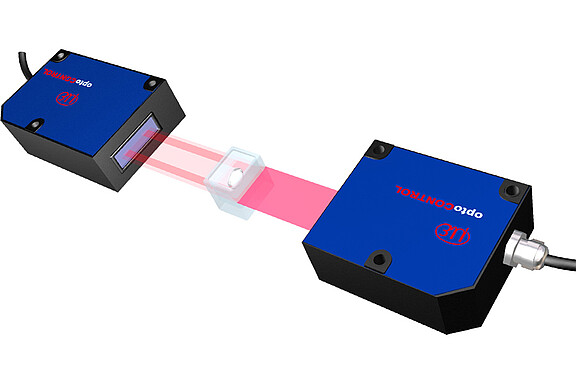

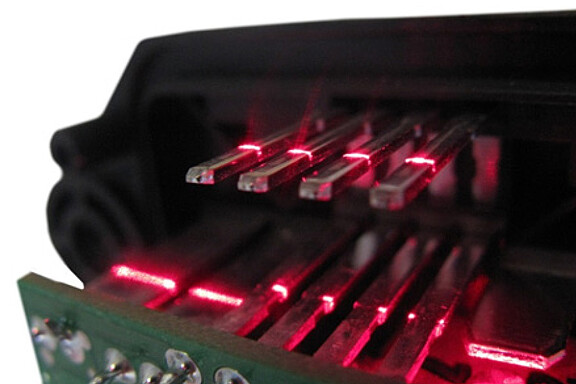

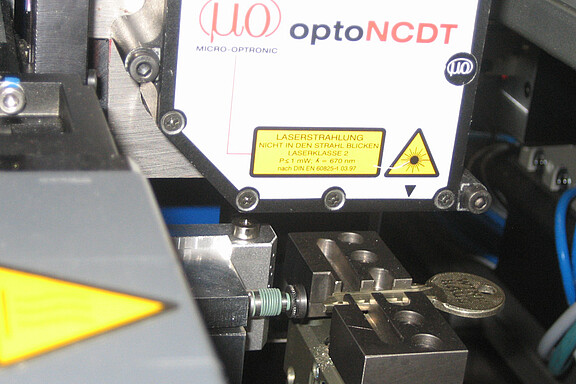

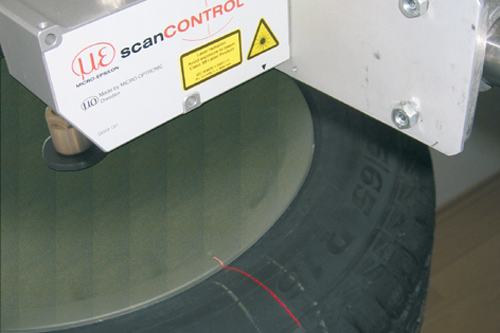

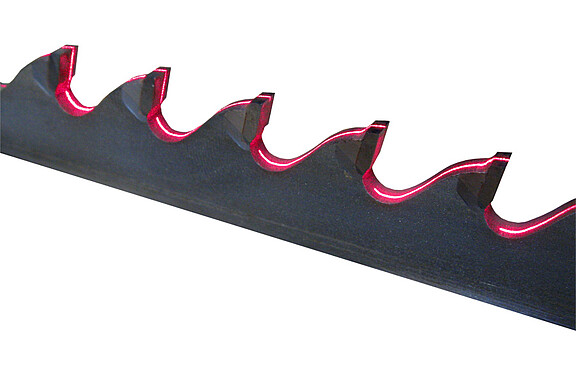

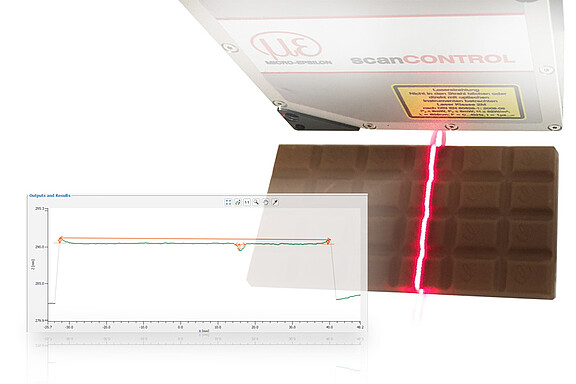

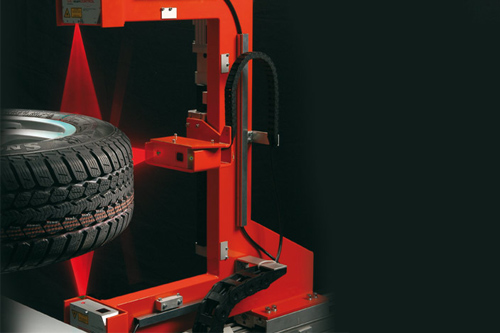

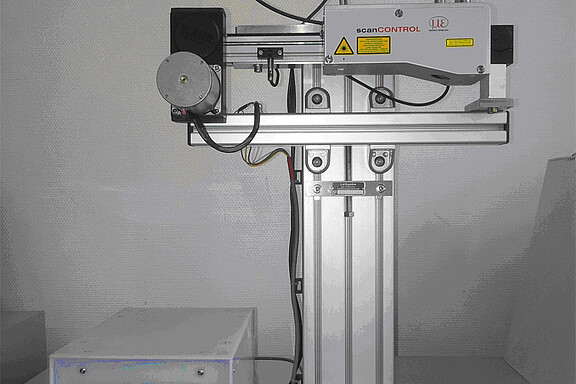

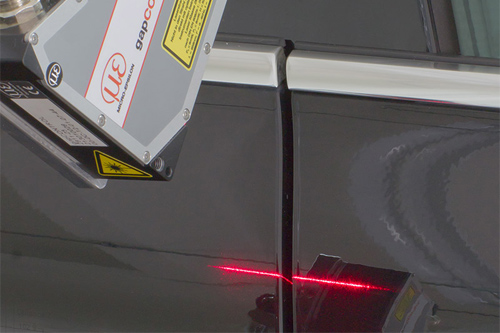

Profile, Contour, Surface

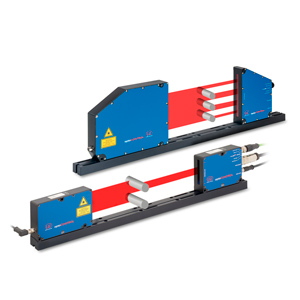

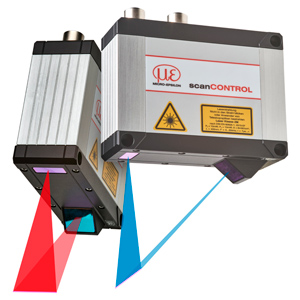

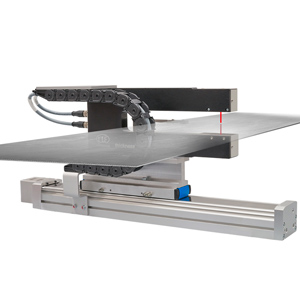

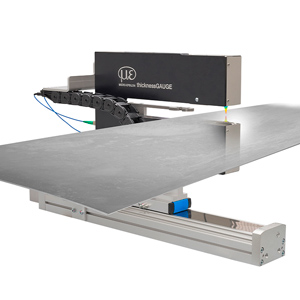

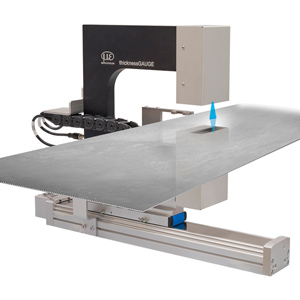

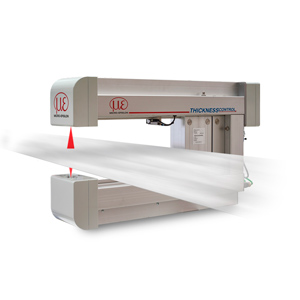

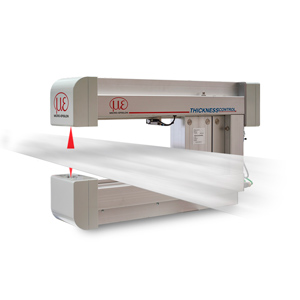

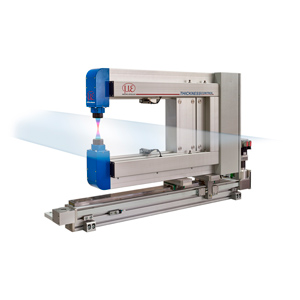

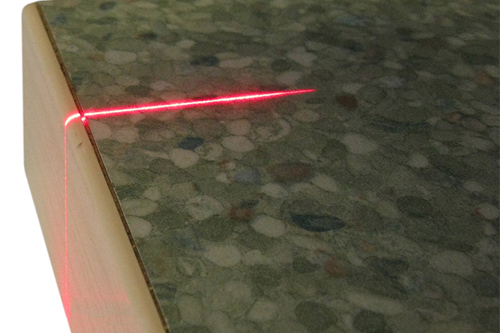

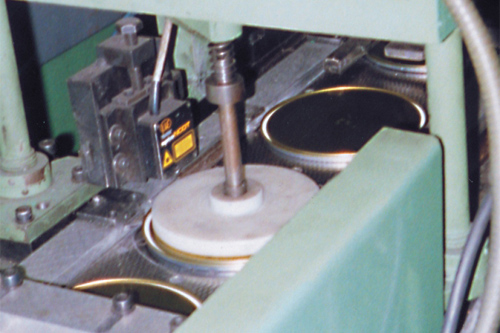

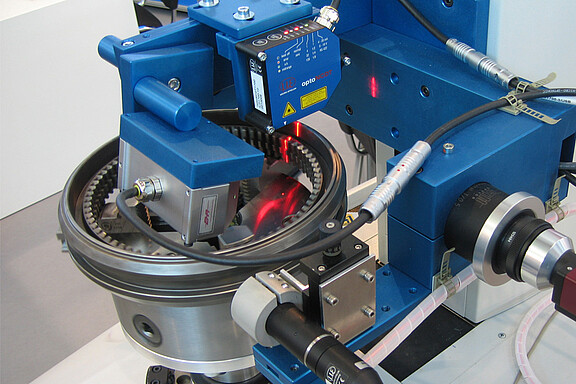

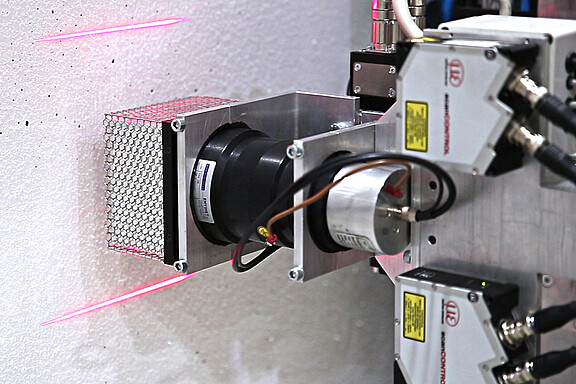

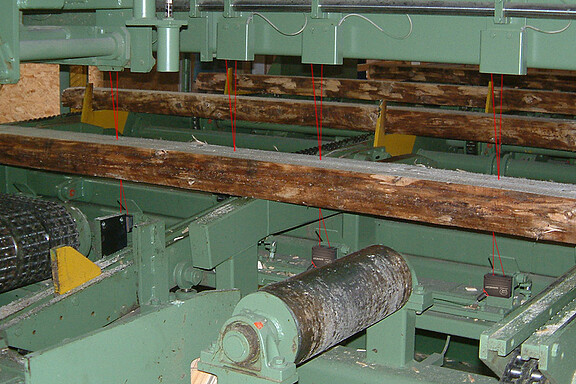

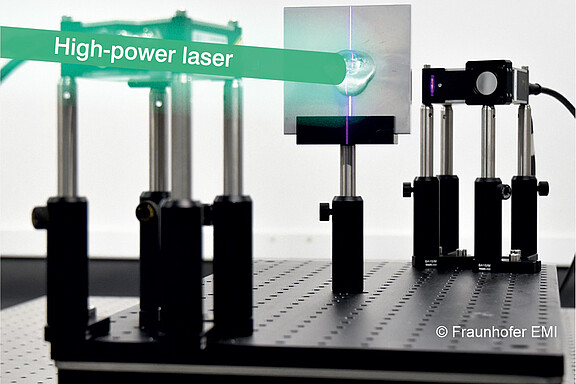

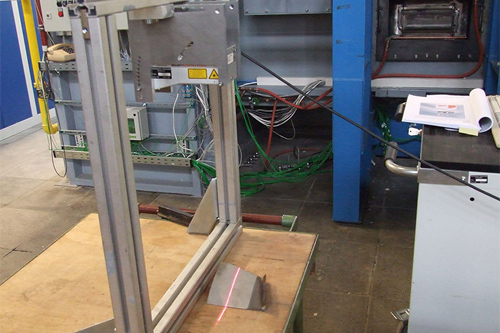

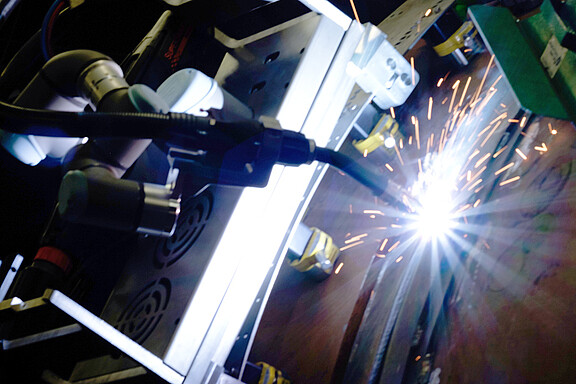

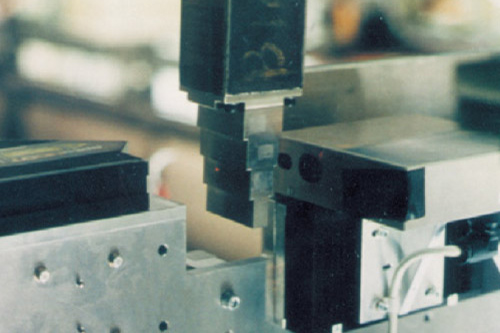

The surface or the surface profile is frequently a decisive factor in quality inspection. Laser scanners from Micro-Epsilon are frequently used for this. If traversing laser point sensors are used, these also measure a profile of the surface. The profile measurement is often used on robots or inspection systems for controlling further processes.