Tire component profilometer - Temperature compensation control

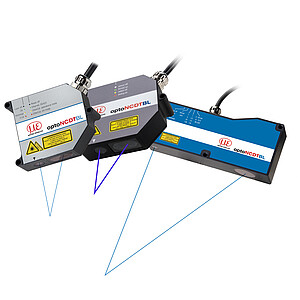

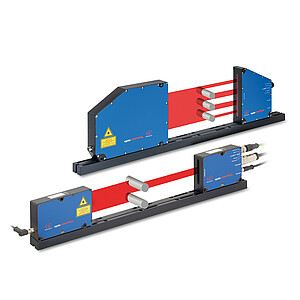

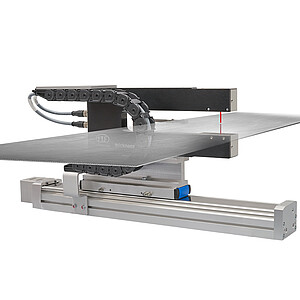

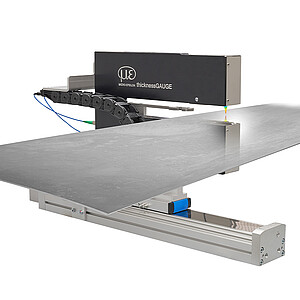

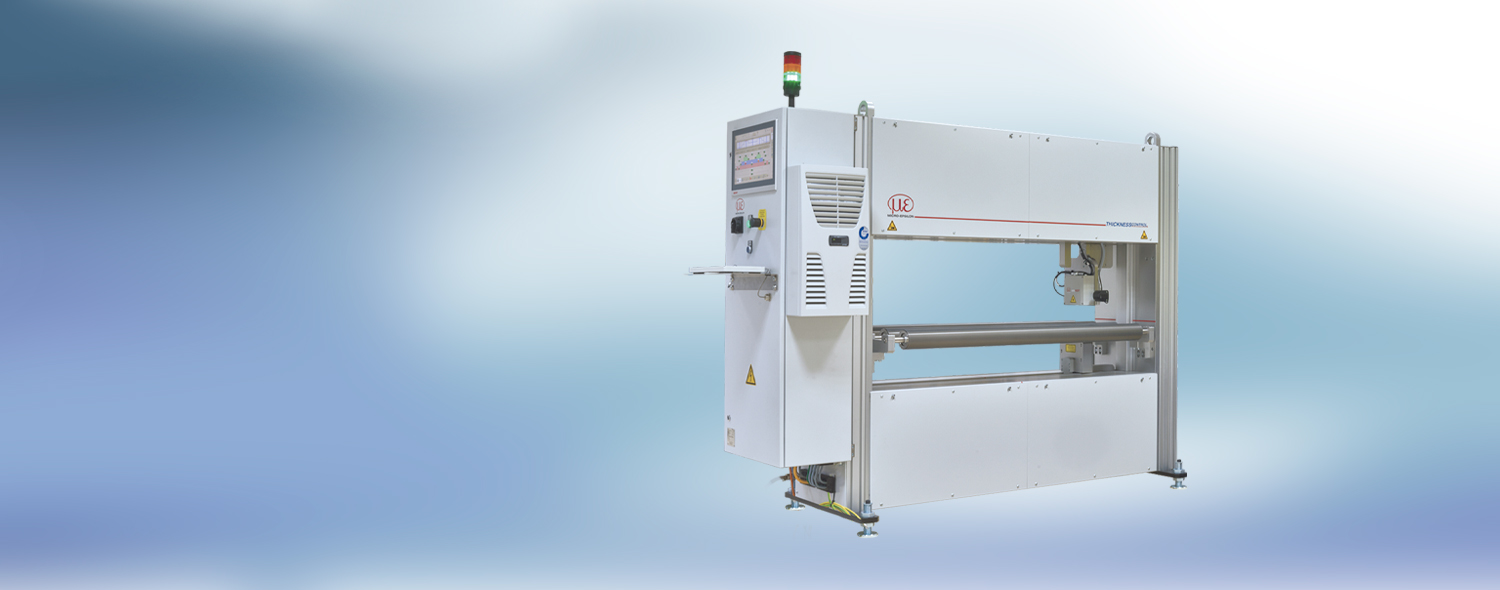

The systems of the thicknessCONTROL TCP 8301.CT/CLLT series are designed as O-frame where the sensors are integrated in the upper and the lower boom. They measure while traversing and achieve high precision due to an innovative coordinated package consisting of sensors, mechanics and software.

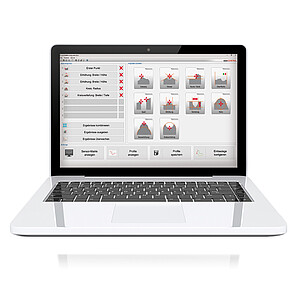

Temperature compensation control

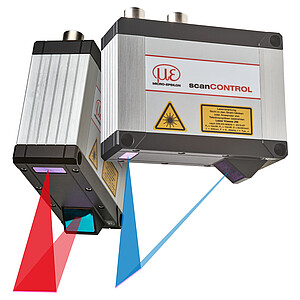

The profilometers operate in differential mode, i.e. the thickness of the material is determined from the difference resulting from the sensor distance and the sum of the sensor signals. A sensor is integrated into each belt of the O-frame on a mechanical carriage. The thickness of the material to be measured results from the offset between the sensors and the measured values. They have efficient cleaning mechanisms that make them highly resistant to vapors and particles. The system is therefore ideally suited for applications in harsh industrial environments. It also enables efficient operation due to long maintenance-free intervals, so that production lines can run uninterrupted for longer. Due to integrated in-situ calibration and temperature invariant components, they are also outstanding under harsh temperature conditions in rubber processing.

All sensor technologies are non-contact, wear-free and measure without isotope or X-ray radiation. They provide reliable long-term data without consequential costs. With a patented closed-loop concept for compensation of temperature-driven expansion effects on the mechanics, the thicknessCONTROL TCP 8301.CT and thicknessCONTROL TCP 8301.CLLT provide revolutionary stability in the ongoing production process.