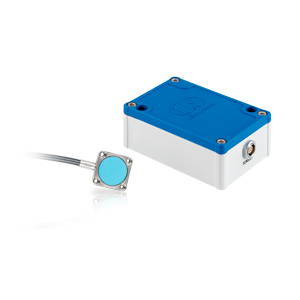

The new confocal chromatic confocalDT IFC2411 and 2416 controllers can perform distance and thickness measurements. The compact and robust controllers set new standards in terms of precision and speed – with high light intensity and a measuring rate…

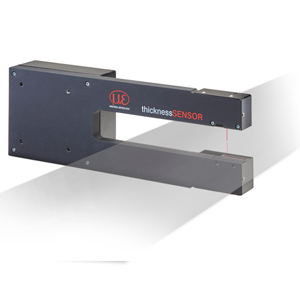

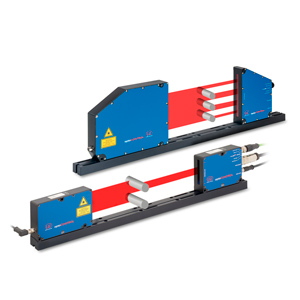

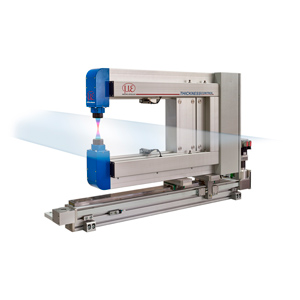

The new optoCONTROL 2700-10 micrometer offers maximum precision for inline quality assurance. It provides a digital resolution of 10 nm and a linearity of ≤ 0.5 µm. It is used for diameter, gap, edge and segment measurements in industrial production…

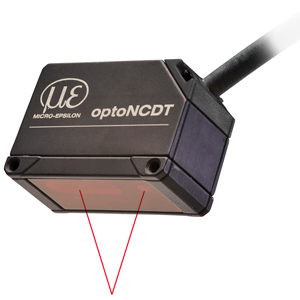

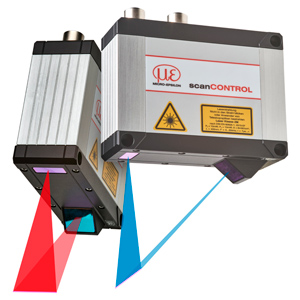

With the new optoNCDT 5500, Micro-Epsilon presents a new generation of laser displacement sensors that are particularly versatile and powerful. The series is available in four different measuring ranges of 10, 25, 100 and 200 mm, with a standard and…